Sn63Pb37 no clean flux core solder wire can offer quite stable welding performance.ĭatasheet of flux core tin leaded alloy Solder Wire Sn63Pb37 It is mid temperature solder wire which its melting point is 183degree Celsius. 63/37 tin lead welding wire represents that the alloy contain 63% tin content and 37% lead content in the solder, the diameter of Sn63Pb37 solder wire is from 0.35mm to 6.0mm. The residue no need to clean.īBIEN TL-01 Sn63-Pb37 flux core solder wire is the most common type and best quality of tin-lead alloy solder, which features the maximum dosage and demand. The flux is more heat stable than most organic fluxes, resulting in minimal smoke and odor. The same fast action and mild properties are exhibited with rosin based flux soldering. This cored solder version Sn-Pb alloy wire is more effective than rosin fluxes in soldering difficult metals. Come on Yeswelder, please give us a few little hints.Flux core tin leaded alloy Solder Wire Sn63Pb37īrief Description for TL-01 Sn63Pb37 solder wireīBIEN TL-01 Sn63/Pb37 leaded no clean pb solder wire is a flux-cored solder wire. I've been in contact with Yeswelder via an help line, and the guy on the other end recommended a Youtube review that shows beautiful welds, but absolutely nothing about the settings used. I have spent hours on line searching, spent a lot of gas, and wire, and aluminum coupons, and destroyed contact tips, and still have very little sense that I'm getting all those settings right. The machine comes with a chart of suggested amperage and wire feed settings, but this gives absolutely no info on pulse settings. Other problems may stem from a lack of information about recommended settings. Part of the problems have come from the spool gun that i ordered with the machine it had a hesitation in the drive mechanism and problems with a seal for the shielding gas. I was excited to try double pulse welding but so far have been sorely disappointed. I am not completely new to aluminum MIG welding having used a spool gun setup on an old Miller machine. I had high hopes for this machine, and so far it has not lived up to the hype. I bought this machine on the strength rave reviews on line. Recommend using YesWelder WP-17V-35 TIG torch.Accessories for TIG welding-TIG torch and tungsten not included.Electrode up to Apply to 9/64" thick carbon steel TIG Welding.Capable of welding with 7018/6011 electrodes.This unit can weld with 7018/6011 electrodes up to 5/32"

A stinger and ground clamp is included with your machine for this process. The YESWELDER MIG-205DS-B can easily run stick electrodes.

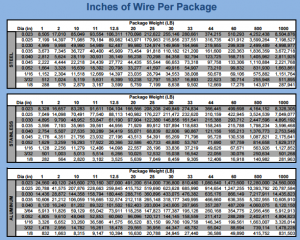

#Flux core wire size chart manual

Manual MIG Setting-meet the need of an experienced and professional welder by adjusting the voltage & wire feeding speed separately. Synergic MIG Setting-provides communication between the power source, feeder, and torch-allows for automatic change of the voltage & wire feeding speed by adjusting the amperage or thicknesses.Suitable for welding carbon steel and aluminum.Apply to D100/D200 rolls (Can take up to 0.9mm(.035") MIG solid wire(Gas MIG) and 0.9mm(.035") MIG FLux wire(Gasless MIG).Aluminum MIG welding available, spool gun compatible.4 Functions in 1 of Gas MIG /Gasless MIG / Lift TIG / Stick.Synergic Controlled & Manual Adjustable MIG function, very easy and simple operation.

0 kommentar(er)

0 kommentar(er)